Add to Cart

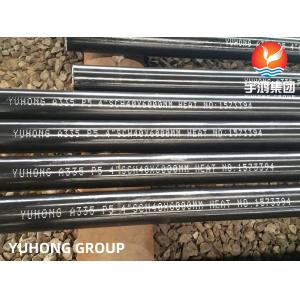

Alloy Steel Seamless Pipe ASTM A335/ASME SA335 P5 P9 P11 P12 P22 P91 P92 for Power Plant Energy Fluid Boiler

ASTM A335 is a seamless ferritic Alloy-Steel Pipe for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Sometimes referred to as "P Grade”, chome moly pipe is popular in P-Grades P5, P9, P11, P22, and P91. The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries

ASTM A335 P5 Pipe Chemical Composition

Chemical composition % of ASTM A335 P5 Alloy Steel Seamless Pipe

| Compositions | Data |

| UNS Designa-tion | K41545 |

| Carbon(max.) | 0.15 |

| Manganese | 0.30-0.60 |

| Phosphorus(max.) | 0.025 |

| Silicon(max.) | 0.50 |

| Chromium | 4.00-6.00 |

| Molybdenum | 0.45-0.65 |

| Other Elements | … |

Mechanical Properties :

| Properties | Data |

| Tensile strength, min, (MPa) | 415 Mpa |

| Yield strength, min, (MPa) | 205 Mpa |

| Elongation, min, (%), L/T | 30/20 |

Heat Treatment :

| P5, P9, P11 and P22 | |||

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

| P5 (b,c) | Full or isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 - 1375 [715 - 745] | |

| P9 | Full or isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P11 | Full or isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| P22 | Full or isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

Alloy Steel Pipe Applications

suitable for high temperature environments including those found in the following industries

Power generation

Petrochemicals

Gas processing