Add to Cart

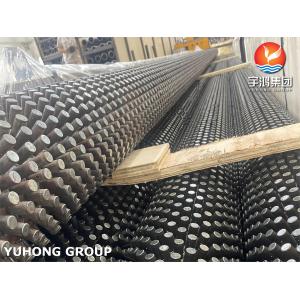

ASTM A213 T9 Alloy Steel Seamless Stud Fin Tube Customized Size

What is studded finned tube?

Studed fin tube is made by electrical resistance welding specially formed studs(round pins ) in rows around the tube. The Studs can be supplied in a variety of sizes and shapes. Stud tube has a very high heat transfer efficiency. The heat exchange efficiency is equivalent to 2-3 times that of the bare pipe.

Finned tubes are used in applications where efficient cooling is required to generate electricity or extract raw materials. Finned tubes are used in condensers, coolers and furnaces. The greater the surface area of finned tubes, the fewer tubes are required compared to using normal tubes. The higher the efficiency of finned tubes, the greater the space and cost savings can be.

Features of a Studded Fin Tube:

-It occupies less space and is, therefore, compact

-Highly durable

-Preferred over Finned tubes as they act as heat transfer systems

-Enhanced performance

Size Reference for Different Types of Fin Tubes

| Type | Description | Base tube | Fin specification (mm) | ||

| O.D. (mm) | Fin pitch | Fin height | Fin thick | ||

| Embedded | G-type fin tueb | 16-63 | 2.1-5 | <17 | ~0.4 |

| Extruded | Single metal combined metal | 8-51 | 1.6-10 | <17 | 0.2-0.4 |

| Low fin tube t-type fin tube | 10-38 | 0.6-2 | <1.6 | ~0.3 | |

| Bamboo tube corrugated tube | 16-51 | 8-30 | <2.5 | / | |

| Wound | l/kl/ll type fin tube | 16-63 | 2.1-5 | <17 | ~0.4 |

| String | String fin tube | 25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-type | U-type tube | 16-38 | / | / | / |

| Welding | HF-welding fin tube | 16-219 | 3-25 | 5-30 | 0.8-3 |

| H/HH type fin tube | 25-63 | 8-30 | <200 | 1.5-3.5 | |

| Studed fin tube | 25-219 | 8-30 | 5-35 | φ5-20 | |

Chemical Composition Of T9

| Cr, % | C, % | P, % | S, % | Mo, % | Mn, % | Si, % |

| 4.00-6.00 | 0.15 max | 0.025 max | 0.025 max | 0.45-0.65 | 0.30-0.60 | 0.50 max |

Mechanical Properties of A213 T9 Alloy Steel Seamless Tubes

| Properties | Data |

| Tensile strength, min, (MPa) | 415 Mpa |

| Yield strength, min, (MPa) | 205 Mpa |

| Elongation, min, (%), L/T | 30/20 |

Equivalent Material of Alloy Steel T9

| ASTM | JIS G 3458 | UNS | BS | ISO |

|---|---|---|---|---|

| T9 | STPA 26 | S50400 | 3604 P1 629-470 | 2604 II TS38 |

Applications:

-Power Plants

-Chemical Industry

-Heat Recovery Plants

-Heat Industry

-Steam Boiler

-Oil Refining