Add to Cart

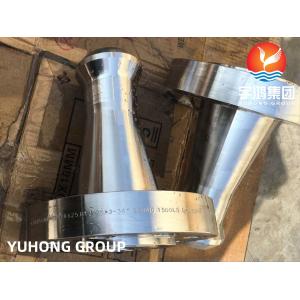

ASTM B564 Inconel 625, UNS N06625, DIN 2.4856 Nickel Alloy Steel RTJ Flange

Inconel Flanges have resistant to oxidation, and this nickel-base alloy functions well at elevated temperatures. In fact, its properties remain unchanged over an extensive temperature range. And like most Inconel alloys, this material has resistant to stress related corrosion cracking to chloride ions. The main applicances of Inconel 625 Forging Flanges include industries like marine and petroleum industries. Other advantages of using the Inconel 625 Flanges are high fracture toughness as well as fabricability. We're manufacturer of ASTM B564 UNS N06625 nickel alloy RTJ flanges with high quality for more than 30 years.

Equivalent Grades:

| STANDARD | GOST | AFNOR | EN | WERKSTOFF NR. | UNS | JIS | BS |

| Inconel 625 | ХН75МБТЮ | NC22DNB4M | NC22DNB4M | 2.4856 | N06625 | NCF 625 | NA 21 |

| Specification: | Inconel 625 Flanges |

| Pressure Rating | 2500 LBS, Class 150 LBS, 900 LBS, 1500 LBS, 300 LBS, 600 LBS |

| common types | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF) Flanges, Large Tongue & Groove Flanges, Flat Face (FF) Flanges, Large Male-Female (LMF) Flanges, Groove Flanges, Lap-Joint Face (LJF) Flanges, Small Male-Female (SMF) Flanges, Small Tongue Flanges, Ring Type Joint (RTJ) Flanges |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Cold and Hot Dip Galvanized, Yellow Transparent, |

| Production technique | Forged, Heat treated and machined |

| Size Chart | 1/2" to 48" |

Chemical Composition:

| Ni | C | Fe | Si | Mn | S | Al | Ti | Nb + Ta | P | Mo | Cr2 |

| 58 min | 0.1 max | 5 max | 0.5 max | 0.5 max | 0.015 max | 0.4 max | 0.4 max | 3.15–4.15 | 0.015 max | 8-10 | 20-23 |

Mechanical Strength:

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Density | Melting Point |

| Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % | 8.4 g/cm3 | 1350 °C (2460 °F) |

Applications:

Pipeline

High Temperature Application

Water Pipe Line

Nuclear Power Plants

Food Processing and Dairy Industries

Boiler & Heat Exchangers