Add to Cart

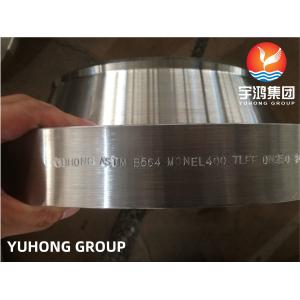

What is monel 400 Flange?

Alloy 400 is highly regarded as one of the best performing engineering alloys. In addition to its excellent corrosion resistance, the primary corrosion resistance of Monel 400 flanges is best suited for use in alkylation units. Concentrated acids, such as hydrofluoric acid and sulfuric acid, are used in these units in the petrochemical industry to convert olefins into alkyl compounds.

MATERIAL COMPOSITION:made of UNS N04400 material, Monel 400, a copper-nickel alloy containing approximately 67% nickel and 30% copper, with small amounts of iron, manganese, and silicon.

Properties: Monel 400 has good corrosion resistance, including resistance to seawater, salt water, acidic and alkaline environments. It also has good mechanical properties, high temperature strength and excellent wear resistance.

Processability: Monel 400 is easy to machine and weld, and can be molded and machined in a variety of ways.

Chemical Composition of ASTM B564 MONEL 400

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

| Monel K500 | 0.25 max | 1.5 max | 0.5 max | 0.010 max | 27.00 – 33.00 | 0.5 – 2 | 63.00 min |

Mechanical Properties of ASTM B564 MONEL 400

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Equivalent Grades of ASTM B564 MONEL 400

| WERKSTOFF NR. | UNS | AFNOR | GOST | JIS | EN | BS |

| 2.4360 | N04400 | NU-30M | МНЖМц 28-2,5-1,5 | NW 4400 | NiCu30Fe | NA 13 |

| Ni | Al | S | C | Mn | Fe | Si | Cu |

| 63.0 min | 0.50 max | 0.02 max | 0.3 max | 2.0 max | 1.0 - 2.5 | 0.5 max | 28.0 - 34.0 |

Application

Oil and gas

Chemical industry

Petrochemical Industry

Plant engineering

marine engineering

Heat exchanger