Add to Cart

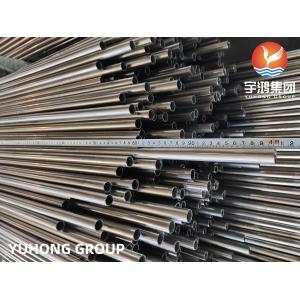

Austenitic Bright Annealed Welded Tube ASME SA249 TP316 316L

ASME SA249 specification specifies austenitic steel welded tubes for heat exchanger system. It is the same with ASTM A249 standard, TP316L stainless steel is typical grade used in special environment, which require good corrosion resistance steel.

The ASME SA249 TP316 Welded Tubing is a pressurized grade that is designed by rolling pieces of sheet and strips followed by welding them in place using filler material. After the welding process, the tubes are subject to testing to ensure that they can be used in harsh environments.

TP316L stainless steel is an Austenitic steel material, it is low carbon content based on TP316, carbon content max 0.035%, and there is Molybdenum (Mo) alloy to be added, therefore, TP316 has good property on corrosion resistance, TP316L grade tubes are usually used in marine environment, particular in sulfuric acid condition.

TP316/316L Chemical Composition, %, Max

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.0 | 11-14 | 16-18 | 2-3 | Balance |

| 316L | 0.035 | 2.00 | 0.045 | 0.030 | 1.0 | 10-14 | 16-18 | 2-3 | Balance |

TP316/316L Stainless Steel Mechanical Properties

| Grade | Tensile Strength(Mpa), Min | Yield Point(Mpa), Min | Elongation(%), Min | Hardness, Max |

|---|---|---|---|---|

| 316 | 515 | 205 | 35 | B90 |

| 316L | 485 | 170 | 35 | B90 |

ASTM A249 316L Tubing Physical Properties

| Grade | Density, (kg/m3) | Specific Heat 0-100°C, (J/kg.K) | Elec Resistivity, (nΩ.m) | Elastic Modulus, (GPa) | Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity, (W/m.K) | |||

| 0-100°C | 0-315°C | 0-538°C | At 100°C | At 500°C | |||||

| ASTM A249 TP316L | 8000 | 500 | 740 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 |

SA 249 TP316 Welded Tubing Wall Thickness

| Normal Pipe Sizes | Wall Thickness | |

| + | – | |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

316 Stainless Steel Round Tube O.D Tolerances

| NPS | Stainless Steel 304 Tube OD Tolerance | |||

|---|---|---|---|---|

| + | – | |||

| inch | mm | inch | mm | |

| 1/8~1 1 /2 > 1 1 /2~4 > 4~8 > 8~18 > 18~26 > 26~34 > 34~48 | 1/64(0.015) 1/32(0.031) 1/16(0.062) 3/32(0.093) 1/8(0.125) 5/32(0.156) 3/16(0.187) | 0.4 0.8 1.6 2.4 3.2 4.0 4.8 | 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) | 0.8 0.8 0.8 0.8 0.8 0.8 0.8 |

Applications

-Off-Shore Oil Drilling Companies

-Power Generation

-Petrochemicals

-Gas Processing

-Specialty Chemicals

-Pharmaceuticals

-Pharmaceutical Equipment

-Chemical Equipment

-Sea Water Equipment

-Heat Exchangers

-Condensers

-Pulp and Paper Industry