Add to Cart

Overview

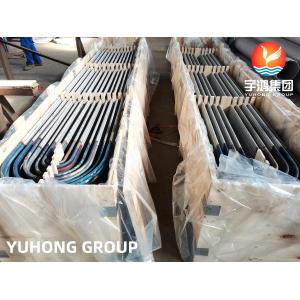

A stainless steel U-bend tube is a type of pipe or tube that has a U-shaped bend in its structure. Here are some key points about stainless steel U-bend tubes:

U-Shaped Bend: A stainless steel U-bend tube is characterized by its U-shaped bend, which allows it to change direction or redirect fluid flow. The bend typically has a 180-degree curvature, resembling the shape of the letter "U."

Stainless Steel Material: U-bend tubes are made from stainless steel, which provides excellent corrosion resistance and durability. Stainless steel offers resistance to various corrosive environments, making it suitable for a wide range of applications.

Heat Exchanger Applications: Stainless steel U-bend tubes are commonly used in heat exchangers, where they facilitate the transfer of heat between two fluids. The U-bend design allows for compact installation and efficient heat transfer in a limited space.

Customizable Dimensions: U-bend tubes can be customized to meet specific application requirements in terms of tube diameter, wall thickness, and bend radius. These dimensions are selected based on the desired fluid flow, heat transfer capacity, and system design.

Welding and Fabrication: Stainless steel U-bend tubes are typically manufactured through a combination of bending, welding, and fabrication processes. The U-bend is formed by bending the tube to the desired shape, followed by welding the two straight ends together to create the U-shaped configuration.

Industry Applications: Stainless steel U-bend tubes find application in industries such as petrochemical, oil and gas, power generation, chemical processing, HVAC, and refrigeration. They are used in heat exchangers, condensers, boilers, and other systems where efficient heat transfer is necessary.

Material Options: Stainless steel U-bend tubes are available in various grades of stainless steel, such as 304, 316, or 316L. The choice of stainless steel grade depends on factors such as the operating temperature, fluid compatibility, and corrosion resistance requirements.

Quality and Standards: Stainless steel U-bend tubes should adhere to industry standards and undergo rigorous quality control measures to ensure their performance and reliability. Compliance with standards such as ASTM, ASME, or specific industry codes ensures the tubes meet the necessary requirements.

Stainless steel U-bend tubes are widely used in heat exchangers and other systems that require efficient heat transfer in a compact space. Their U-shaped bend allows for redirection of fluid flow or change in direction. Customization options, material choices, and adherence to quality standards are important considerations to ensure optimal performance in specific applications.

Features:

Chemical Composition

Grade |

| C | Mn | Si | P | S | Cr | Mo | Ni | N |

316 | Min | - | - | - | 0 | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

316H | Min | 0.04 | 0.04 | 0 | - | - | 16.0 | 2.00 | 10.0 | - |

max | 0.10 | 0.10 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | - |

Mechanical Properties

Grade | Tensile Str | Yield Str | Elong | Hardness | |

Rockwell B (HR B) max | Brinell (HB) max | ||||

316 | 515 | 205 | 40 | 95 | 217 |

316L | 485 | 170 | 40 | 95 | 217 |

316H | 515 | 205 | 40 | 95 | 217 |

Application: