Add to Cart

Hastelloy C276 is a corrosion-resistant nickel-molybdenum-chromium alloy that is highly versatile and offers excellent resistance to a wide range of corrosive environments. Hastelloy C276 flanges are commonly used in industries where corrosive chemicals, acids, and high temperatures are present. Some of the common applications and industries where Hastelloy C276 flanges are used include:

Overall, Hastelloy C276 flanges are known for their exceptional corrosion resistance, high strength, and versatility, making them a preferred choice for a wide range of industries and applications where corrosion-resistant materials are required.

Equivalent Grades for Hastelloy Alloy C276

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | OR | GOST |

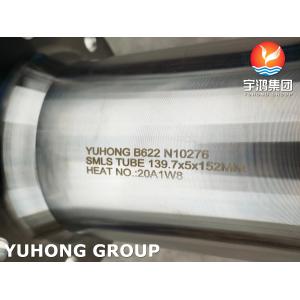

| Hastelloy C276 | N10276 | 2.4819 | - | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |

Chemical Composition for Hastelloy Alloy C276

| Hastelloy C276 | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr |

| Balance | 0.010 max | 15.00 – 17.00 | 1.00 max | 0.08 max | 4.00 – 7.00 | 0.04 max | 0.03 max | 2.5 max | 14.50 – 16.50 |

Mechanical Properties for Hastelloy Alloy C276

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 52,000 , MPa – 355 | Psi – 1,15,000 , MPa – 790 | 40 % |

Raised Face Long Weld Neck Flange Tolerance

| ASME B16.5 | Tolerance | |

|---|---|---|

| A | Outside Diameter (O.D.) |

|

| D | Inside Diameter |

|

| B | Diameter of contact face |

|

| J | Diameter of hub at base |

|

| H | Diameter of hub at point of welding |

|

| P | Drilling |

|

| Eccentricity of bolt circle with respect to facing |

| |

| C | Thickness |

|

| K | Length of hub |

|