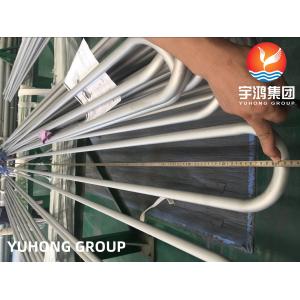

ASTM B444 INCONEL 625 U BEND TUBE (UNS NO6625 , DIN 2.4856) HEAT EXCHANGER APPLICATION

INCONEL 625 characteristics:

- 1. High creep-rupture strength

- 2. Oxidation resistant to 1800° F

- 3. Seawater pitting and crevice corrosion resistant

- 4. Immune to chloride ion stress corrosion cracking

- 5. Non-magnetic

Inconel 625 application:

- 1. Aircraft ducting systems

- 2. Aerospace

- 3. Jet engine exhaust systems

- 4. Engine thrust-reverser systems

- 5. Specialized seawater equipment

- 6. Chemical process equipment

Overview

Inconel 625 is a corrosion and oxidation resistant nickel alloy that is used both for its high strength and outstanding aqueous corrosion resistance. Its outstanding strength and toughness is due to the addition of niobium which acts with the molybdenum to stiffen the alloy’s matrix. Alloy 625 has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is frequently used to weld AL-6XN. This alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. Some typical applications Inconel 625 is used in are chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors.

Chemical Composition

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C | Fe | Mn | Si | P | S |

| 20.00-30.00 | Remainder | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max | 5.0 max | .50 max | .50 max | .015 max | .015 max |

Mechanical Properties

| Temp° F | Tensile (psi) | .2% Yield (psi) | Elongation in 2"(%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting | Wire |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Fabrication with Inconel 625

Alloy 625 has excellent forming and welding characteristics. It may be forged or hot worked providing temperature is maintained in the range of about 1800-2150° F. Ideally, to control grain size, finish hot working operations should be performed at the lower end of the temperature range. Because of its good ductility, alloy 625 is also readily formed by cold working. However, the alloy does work-harden rapidly so intermediate annealing treatments may be needed for complex component forming operations. In order to restore the best balance of properties, all hot or cold worked parts should be annealed and rapidly cooled. This nickel alloy can be welded by both manual and automatic welding methods, including gas tungsten arc, gas metal arc, electron beam and resistance welding. It exhibits good restraint welding characteristics.