Add to Cart

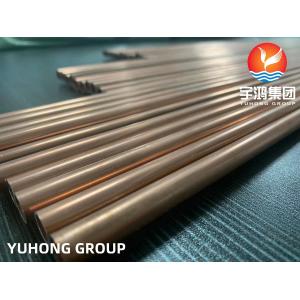

Carbon Steel Copper Coated alloy Tube Bundy Steel for automobile Usage

Bundy tube, sometimes called Bundy pipe, is type of double-walled low-carbon steel tube manufactured by rolling a copper-coated steel strip through 720 degrees and resistance brazing the overlapped seam in a process called Bundywelding

Bundy Tube

It covers single-wall, double-wall, copper-brazed steel tubing, zinc-coated steel tubing suitable for general engineering uses, particularly in the automotive, refrigeration, and stove industries for fuel lines, brake lines, oil lines, heating and cooling units, and the like. The tubing is available in either of two types, single strip or double strip. It is delivered in straight length or coil type.

Electro-welded Single Wall Steel Tubing

Single wall steel tubing is the most common type of tubing used in household refrigeration applications. Bundy single wall tubing is manufactured by continuously forming a single low carbon steel strip into a tubular shape and welding the adjoining edges using a high frequency induction welding process. Through strict process controls, the internal weld bead is held to a minimum and all external flashing is removed. Corrosion resistant coatings are applied in-line to assure uniform coverage

Physical Performance Parameters:

| Tensile Strength | ≥180Mpa |

|---|---|

| Yield Strength | ≥290Mpa |

| Enlongation rate | ≥25% |

| HR30T | ≤68 |

| Innernal cleanliness | ≤0.16g/suqare meter |

Size and Tolerance

| Outer diameter (φ) | Diameter tolerance (mm) | Wall thickness(mm) | Wall thickness tolerance(mm) | Pressure resistance(MPa) | Burst pressure (MPa) |

| 4.76(3/16″) | ±0.05 | 0.7 | +0.05/-0.08 | 41.2 | 110 |

| 6 | ±0.08 | ±0.08 | 32.7 | 85 | |

| 6.35(1/4″) | ±0.08 | ±0.08 | 30.9 | 78 | |

| 8(5/16″) | ±0.1 | ±0.08 | 24.5 | 67.5 | |

| 9.52(3/8″) | ±0.1 | ±0.08 | 20.6 | 57 | |

| 10 | ±0.1 | ±0.08 | 19.6 | 55 | |

| 12 | ±0.1 | ±0.08 | 16.3 | 32 | |

| 10 | ±0.1 | 1 | ±0.08 | 28 | 65 |

| 12 | ±0.1 | ±0.08 | 23.3 | 56 |

Applications:

Air Condition or Refrigerator, Fluid Pipe, Automotive Parts.

Mainly used for oil pressure gauge pipes, fuel pipes, brake pipes and similar devices in the automobile industry, refrigeration industry, heater manufacturing industry, and can also be widely used to replace copper pipes to reduce the cost of use.