Add to Cart

Overview:

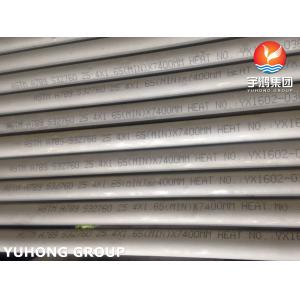

The tubing made form ASTM A789 UNS S32760 is a super duplex stainless steel (SDSS) tube. UNS S32760 has guaranteed corrosion performance with the PREN value no less than 40. Similar to UNS S32750, it has excellent resistance to chloride stress corrosion cracking (SCC) and pitting corrosion; it also has much higher strength than the austenitic stainless steels and better impact toughness than ferritic stainless steels. ASTM A789 UNS S32760 tubing is generally furnished with actual outside diameter, minmum or average wall thickness. They are primarily used for services requiring general corrosion resistance, with particular emphasis on resistance to SCC. The tubing are susceptible to embrittlment if used for prolonged periods at moderately elevated temperature. UNS S32760 has a proprietary brand name of “Zeron 100”.

Specification:

| Standard | ASTM A789 & Its equivalent ASME, DIN & EN Standard |

| Grades | S32760 |

| Type | Seamless or Welded |

| Outer Diameter Size | 1/4'' to 6'' or as required |

| Wall Thickness | 0.02'' to 0.5'' or as required |

| Length | Upto 6 meters or custom cut lengths |

| Finishes | Annealing Pickling |

| Ends | Plain End, Beveled End |

| Other Testing | Product Analysis, Radiographic Examination, Transverse Tension Test, Flattening Test, Etching Test, Stabilizing Heat Treatment, Intergranular Corrosion Test, Grain Size Test, NACE 0175, Dual Grade, Weld Decay Test, Magnetic Particle Detection, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

| Dimension | All Pipe & Tube Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Packaging | Loose / Bundle / Plastic Cloth Wraps / Wooden Pallet / Wooden Box / Plastic End Caps / Beveled Protector |

Chemical Composition:

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu | W |

| S32760 | 0.03 max | 1.00 max | 0.03 max | 0.01 max | 1.00 max | 6.0-8.0 | 18.0-20.0 | 3.0-4.0 | 0.20-0.30 | 0.50-1.00 | 0.50-1.00 |

Mechanical Properties:

| Grade | Density | Tensile Strength, min, ksi (MPa) | Yield Strength, | Elongation in 2 in. | Hardness | Solutioning Temperature, | |

| Rockwell | Brinell/Vickers | ||||||

| S32760 | 7.8 | 109(750) | 80(550) | 25 | 32HRC | 310HBW/310HV | 1960-2085 |

Application:

1.Chemical Process Industry: Due to its high corrosion resistance UNS S32760 is ideal for use in Nitric Acid Processes, Polypropylene 2.Production, PVC Production, Dioxide, Caustic Evaporators, and Equipment.

3.Handling Organic and Fatty Acids.

4.Marine Industry and Shipbuilding: Propellers and Shafts, Rudders, Shaft Seals, Pumps, Bolts and Fasteners, Valves, Instrumentation, Oil and 5.Chemical Tankers

6.Oil and Gas Industry: Pumps, Valves, Pipe, Vessels, Wellhead Equipment, Subsea Equipment

7.Pollution Control: Fans and pumps, Wet Scrubbers, Incinerators

8.Pulp and Paper Industry: Black liquor heater tubes, Digester Blow Valves, Rotary Feed Valves, I.D.Fans, Brownstock Washers, Precipitators, 9.Bleaching Components

10.Food Industry: Sugar Cane Centrifuges, Corn and Vegetable processing plant

11.Agrochemicals: Fertilizer Production (Wet phosphoric acid)

12.Civil Engineering: Sewage Treatment